Flocking is a process that uses the physical characteristics of homogeneous repulsion, opposite attraction, and physical attraction to make the fleece negatively charged, and to place the ready-to-flocked object under zero potential or ground.

The flock is absorded by the plant body with different potentials, and then accelerates vertically to the surface of the ready-to-flocked object. As the plant body is coated with an adhesive, the flock could be stuck vertically to the plant body directly. Therefore, electrostatic flocking is a new production process that uses the natural characteristics of electric charges.

We can choose the appropriate flocking method according to differet flocking products, can they can be generally divided into three types:

1.Flocking machine with assembly line: This flocking assembly line can be used automatically from the gluing, flocking, drying and floating of the items.

The raw material could be: cloth, leather, paper, non-woven fabric, PVC, blister sheet, sponge, all kinds of crafts, toys, automotive plastic parts, storage boxes, automotive sealing strips, trim strips, plastic boxes, cardboard , Wall calendar, couplets, new year pictures, flocking printing for gift boxes.

2.Box flocking: Make a flocking box according to the size and shape of the need-to-flocked product,and place the fluff in the box, then turn on the power. In such way, a high-voltage electric field is formed in the flocking box. After three to five seconds of the products putting inside of the box, it will be removed from the other end of the box after flocking, and dried or air-dried to be the finished product.

Advertisement

This is for relatively small products, which can be placed in the box flocking directly without any manual flocking.

3.Nozzle-type spray flocking: Turning on the power, the tens of thousands of volts of high-voltage static electricity generated by the flocking machine is output to the industrial nozzle, the fluff in the nozzle is negatively charged, and then the surface of the plant is sprayed with adhesive, and the nozzle is moved closer Under the action of a high-voltage electric field, the flocks of flocked objects fly from the nozzle to the surface of the flocked objects, and are planted vertically on the surface of the object coated with adhesive.

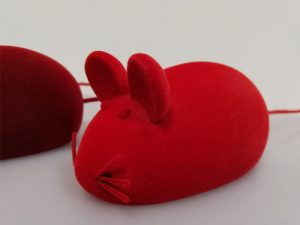

This flocking way is applied to the objects with no size limition. And it is much more common used in flocking process. In the next article, we would like to talk about the 2019 CNY flocking display props for Max Mara, which is made by this such nozzle-type spray flocking way.

Information collected from DM Window Display

Photo Gallery2 weeks ago

Photo Gallery2 weeks ago

Headlines5 days ago

Headlines5 days ago

Headlines1 week ago

Headlines1 week ago

Headlines2 weeks ago

Headlines2 weeks ago

Headlines2 weeks ago

Headlines2 weeks ago

Headlines4 days ago

Headlines4 days ago

Headlines3 days ago

Headlines3 days ago

Designer Dozen1 week ago

Designer Dozen1 week ago